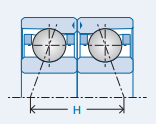

Back to Back Pair

GMN Bearing USA’s ABEC 7 high precision ball bearings are made for high speed and heavy load applications.

Angular Contact Bearings must be purchased and installed in sets for machine applications to function correctly.

Angular contact bearing arrangements help your application achieve maximum productivity and efficiency.

A few benefits of preloading a bearing:

Multiple bearing arrangements form bearing sets to increase load capacity, rigidity and lift-off force.

For rigid bearing preload, matched bearing pairs in O, X or tandem arrangements provide an effective economic and technical solution to a lot of different applications.

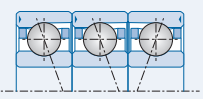

Back to Back Pair

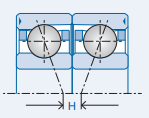

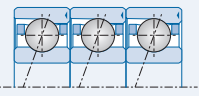

Face to Face Pair

Requires an opposing load from other bearing(s) or another source.

Where there are maximum demands on system rigidity or high loading, the X, O or Tandem arrangements with three or more bearings are able to attain outstanding performance characteristics.

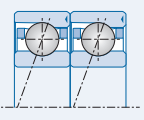

Good for heavy shaft loading from left to right. Requires an opposing load from other bearing(s) or another source.

Good for heavy shaft loading from right to left.

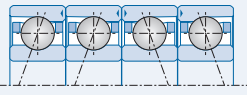

Good for very heavy shaft loading from left to right.

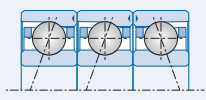

Common quad bearing arrangement.

For very heavy shaft loading from left to right. Requires an opposing load from other bearing(s) or another source.

Good for heavy shaft loading from left to right.

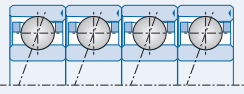

Common quad bearing arrangement. Face to Face Arrangement with spacers: Sometimes called a ‘Big F’.

Installing spacers can offer distinct optimization features to your application. Always make sure that the width of the spacer is as wide as a single bearing.

Installing spacers can offer distinct optimization features to your application. Always make sure that the width of the spacer is as wide as a single bearing.

Benefits of using spacers: