GMN Bearing USA’s ABEC 7 high precision ball bearings are made for high speed and heavy load applications.

- Home

-

Precision Bearings

Precision Bearings Browse All »

-

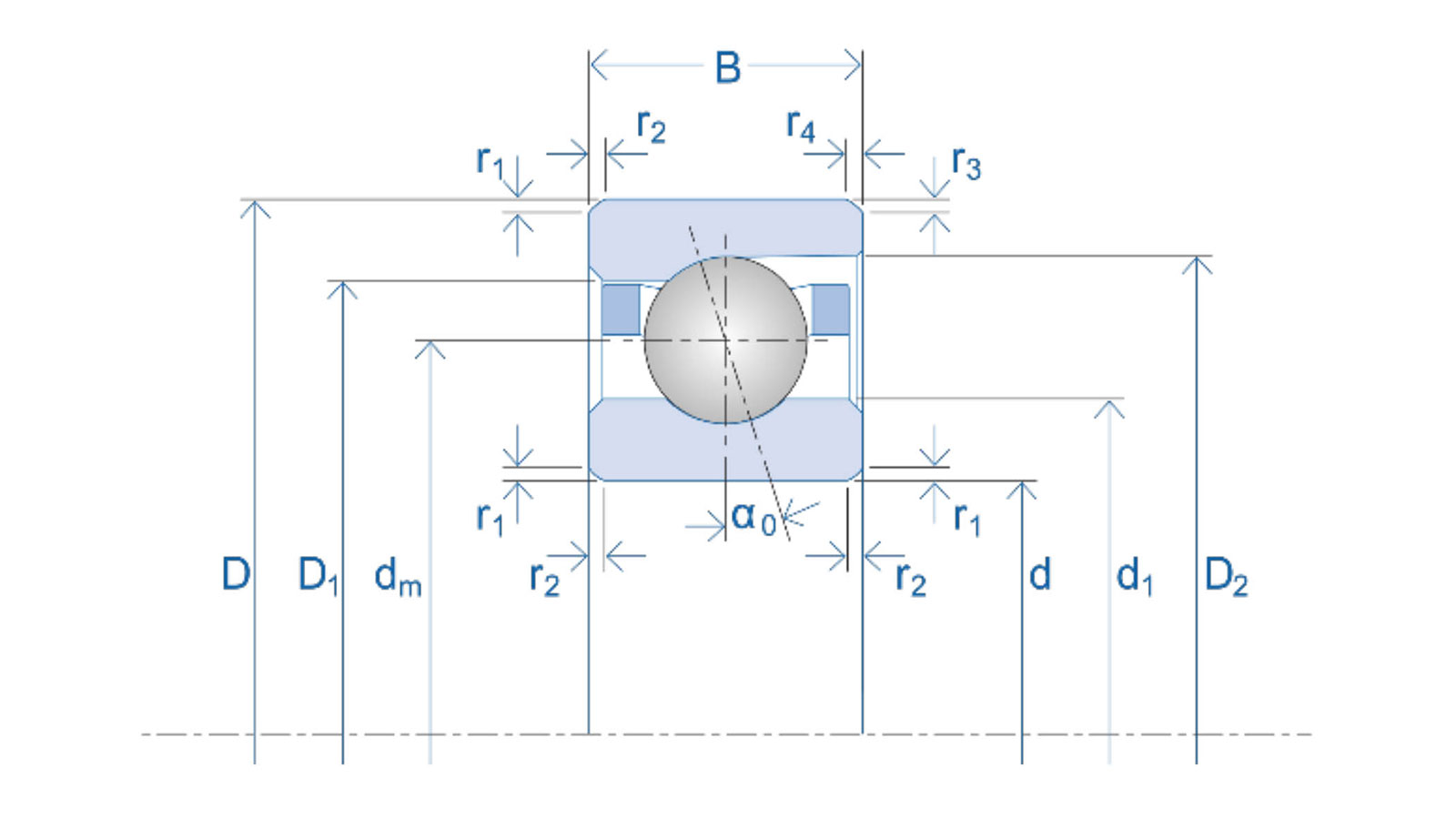

Angular Contact Ball Bearings

Angular Contact Ball Bearings

GMN angular contact bearings (spindle bearings) are expertly crafted for speed, precision, & accuracy.

-

Radial Ball Bearings

Radial Ball Bearings

GMN radial ball bearings are versatile, great in small spaces & when axial loads move in both directions.

-

Other Bearing Brands

Other Bearing Brands

We know that not every application requires super, high-precision bearings. We stock other industrial parts from quality brands.

-

-

Clutches

Clutches Browse All »

Our one-way sprag clutches are great for applications with low to high torque capacity.

-

Complete Sprag Clutch Units

Complete Sprag Clutch Units

Includes built-in ball bearing support. Supports HEAVY loads & has a high torque capacity: 53 to 588 Nm. Bore (ID) sizes: 10 to 60 mm (0.393 to 2.362 in)

-

Ball Bearing Sprag Clutch Units

Ball Bearing Sprag Clutch Units

Includes built-in ball bearing support. Supports MEDIUM loads & low to medium torque capacity: 53 to 267 Nm. Bore (ID) sizes: 17 to 40 mm (0.669 to 1.57 in)

-

Sprag Clutch Elements (400 Series)

Sprag Clutch Elements (400 Series)

No built-in ball bearing support. Good for large orders & low to high torque needs: 1 to 2673 Nm. Bore (ID) sizes: 2 to 240 mm (0.078 to 9.448 in)

-

No RPM Limit FE 8000 Series

No RPM Limit FE 8000 Series

No built-in ball bearing support. Has no RPM limits & Supports high torque needs: 609 to 14,060 Nm. Bore (ID) sizes: 38.09 to 220 mm (1.499 to 8.66 in)

-

Backstopping Clutch with Mounting Tab

Backstopping Clutch with Mounting Tab

This heavy-duty clutch (aka a hold-back clutch) is good for high torque operations and ensures motion freezes in place. Bore (ID) sizes: 15 to 40 mm. (0.59 to 1.73 in)

-

Roller Ramp Clutches

Roller Ramp Clutches

Designed for HEAVY-DUTY applications that require tough durability.

-

-

Non-Contact Labyrinth Seals

Non-Contact Labyrinth Seals Browse All »

Our non-contact labyrinth seals are the first line of protection for bearing systems.

-

CF Seals

CF Seals

The best protection for your bearing. Easy to install with a simple “drop-in” next to your bearing. No added space needed. CF seals offer 100% sealing efficiency against splashing liquids.

-

L Seals

L Seals

Protection against low contamination & splashing liquids.

-

M Seals

M Seals

Designed with grooves in the outer ring to offer more protection (than our L-type seal) against contamination and direct spray liquids. Liquid gets pushed out through outer grooves when in rotation.

-

S Seals (Gap Seals)

S Seals (Gap Seals)

Our GMN Gap Seals are plastic and a great choice for washdown applications, such as food conveyors and food manufacturing facilities

-

- Engineering

- Tools & Resources