Protect Against Heavy Amounts of Contamination & Splashing Liquids.

Our CF Seals offer the best protection for all types of environmental contamination and splashing liquids.

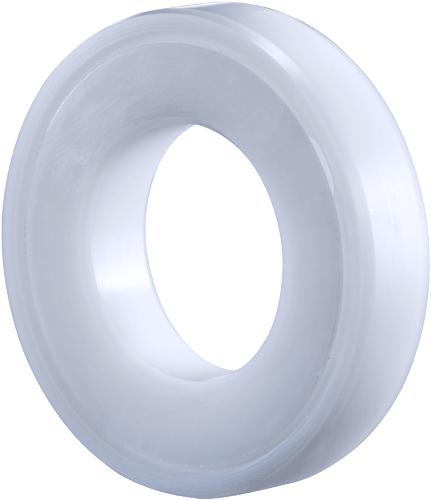

CF Seals are proprietary to GMN and are the newest advancement in non-contact, labyrinth seal technology.

CF Seals sit directly against the bearing, eliminating the need for added space inside a spindle and they offer 100% sealing efficiency against splashing liquids.

CF Seal stats-at-a-glance:

- Shaft Diameter (d) (mm): 10 to 100

- Outer Diameter (D) (mm): 30 to 150

- Width (mm): 6

- Material Choices: Nitride Steel or Aluminum

- Max Temp: -40° F (-40° C) to 392° F (200° C) (Aluminum)

- Matched bearing sizes