Application Conditions

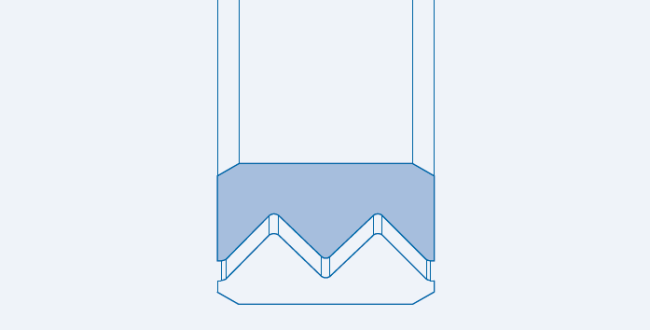

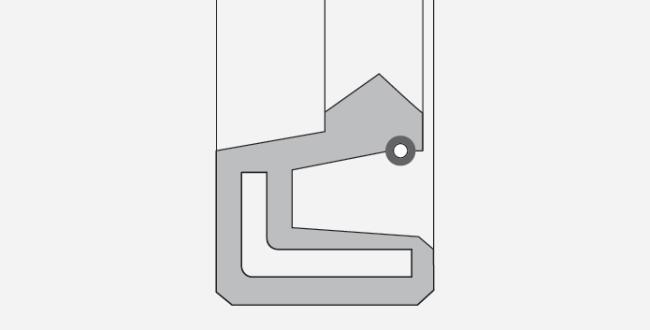

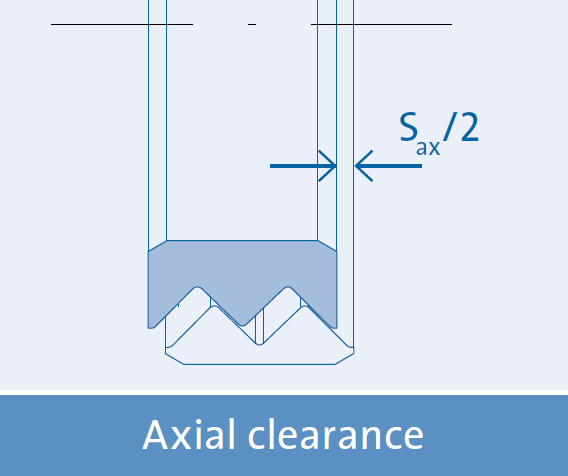

Labyrinth seals are designed to function extremely well protecting sensitive components like bearings from both liquid and airborne particulates. This includes dirty or dusty environments and applications with splashing liquids like machine tool cutting fluid or other coolants. The seals can also be used to keep grease or oil inside the system to protect sensitive equipment or environments outside. This includes gearboxes with oil splashing and greased bearings.

Because the seals are non-contact and rely on a labyrinth path with centrifugal forces for sealing, there are some applications for which these seals are not optimal. This includes applications where the seals would be required to maintain a pressure differential or prevent a standing level of liquid from egressing through the seal. The pressure created by the differential, or the standing level of liquid would overcome the seal characteristics and leakage would occur.

Applications with low RPMs can utilize a labyrinth seal. These situations would call for the use of GMN's CF seal that is designed with a complex labyrinth path to properly function at low speeds.

Improve Food Manufacturing Processes with GMN Bearing USA

It is worth noting that in the food production industry, there are specific requirements for cleanliness, hygiene, and resistance to contamination. In such applications, GMN bearings offer special features like a shielded/sealed design.

It is worth noting that in the food production industry, there are specific requirements for cleanliness, hygiene, and resistance to contamination. In such applications, GMN bearings offer special features like a shielded/sealed design.

This application is where our labyrinth seals shine, especially our S & SA Type seals. These types are made from high quality - food grade - POM plastic which resists corrosion. These seals stand up to heavy splashing - perfect for when equipment is routinely washed down.

Learn more about the markets and applications we serve.

It is worth noting that in the

It is worth noting that in the