Fast Speeds, Heavy Loads

The S “standard” series bearing adapts to many different speeds, loads and other variables.

This series fits shafts with a max ID of 120 mm and supports max RPM speeds of 195,000 (steel) / 243,750 (ceramic).

Angular contact bearings support both radial and axial loads and are designed to operate at high speeds for vast amounts of time. Also known as spindle bearings, GMN angular contact bearings are beneficial for applications that:

Our ABEC 7 angular contact bearings are manufactured in Nürnberg, Germany, and stocked in Houston, Texas. We have one of the largest in-stock inventories of angular contact bearings in N. America.

We are a precision bearing company located in Houston, Texas, and the only authorized distributor of GMN precision components in the USA.

Our three angular contact bearing product lines include our Standard (S), SM, and KH series.

We ship orders the same day the PO is sent (as long as the PO is sent by 3:30 pm CST). Most of our precision bearings are in stock and ready to ship out from Houston, Texas.

Fast Speeds, Heavy Loads

The S “standard” series bearing adapts to many different speeds, loads and other variables.

This series fits shafts with a max ID of 120 mm and supports max RPM speeds of 195,000 (steel) / 243,750 (ceramic).

Faster Speeds, Medium Loads

Compared to our S Series, the SM can support speeds about ~ 20% faster w/ medium loads.

The SM series fits shafts with a max ID of 120 mm and supports max RPM speeds of 230,000 (steel) / 287,500 (ceramic).

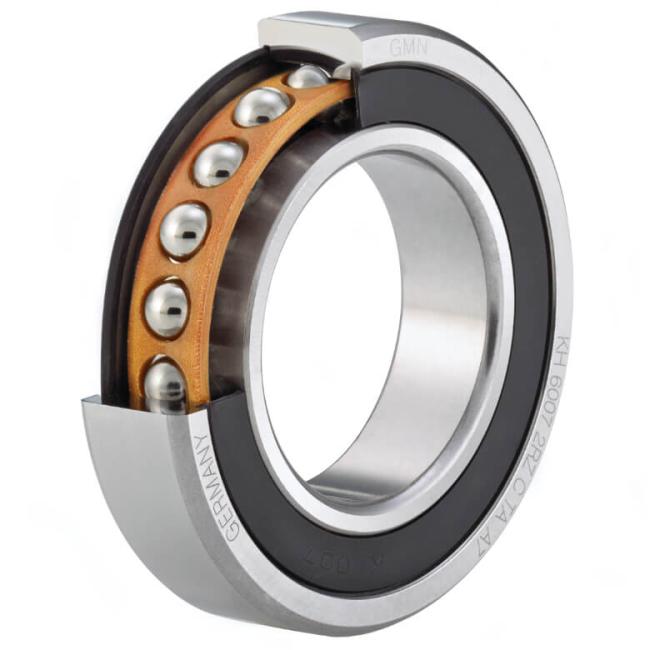

Fastest Speeds, Light Loads

Our KH series is optimized to support the fastest speeds. Choose this bearing if you need seals (also comes open).

The KH series fits shafts with a max ID of 70 mm and supports max RPM speeds of 135,000 (steel) / 168,750 (ceramic).

We understand that some machine applications have different and unique bearing requirements. Some may need heavier load capabilities or faster operational speeds. We strive to offer a truly customizable approach for our angular contact bearings.

Our bearing experts can help you find the optimal bearing for your application. Give us a call today!

Our goal is to make sure every machine and application has the right precision angular contact bearing. If you are unsure about what bearing is best for your application, contact us!

Bearing precision is important, especially if your equipment is being used at maximum speeds. Precision classes guide the properties of bearings to ensure uniformity and regulation standards are met.

Standards are usually represented in ABEC, DIN or ISO classes.

![]()

![]()

Our in-house engineers at GMN Bearing USA offer best in class support to help you improve the performance of your application with proper ball bearing installation and maintenance. We work with several industries and applications including: